We have created a sea of plastic, literally.

This seems to be today’s most prevalent Public Service Announcement!

Even though I’m not quite clear how my discarded plastic is ending up in the ocean, I really do think it’s incumbent on everyone to do their part in cutting back. So, in my overzealous way, I decided to go plastic free.

That was until I went shopping and realized just how very impossible that would be – at least right now.

So, while I wait for more technology to be developed and more products to be packaged in biodegradable containers, a small step I can take is to make my own reusable produce bags.

The first step was to research fabric options.

I ended up finding a company called Wazoodle Fabrics who specialized in Eco-Friendly fabrics.

They are located in Bensalem, PA and it appears that the majority of their fabrics are manufactured here in the US and a very small percentage made in Canada.

Wazoodle it turns out, manufacturers fabrics for all sorts of things – I had no idea there were so many people out there sewing in an eco-friendly way.

Their fabrics include: Antimicrobial, Waterproof, Food Safe, Lycra Stretch-FIT, ProCool Athletic, Ready-AbZORB, Bamboo, Organic Cotton, Hemp, Wool, Microfiber Fleece, and more.

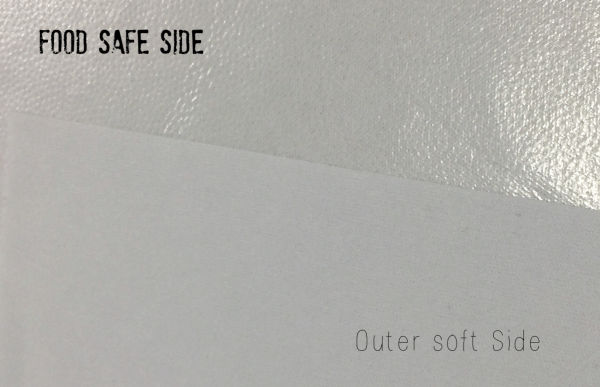

The prices were reasonable so I ordered a yard – of 60” wide Food Safe fabric I figured would make several bags. I received my purchase several days later.

It wasn’t what I was expecting. For some odd-reason, I was thinking it would be transparent. This had to be my “imagination” overriding my brains though because there was nothing in the description to indicate the fabric was anything other than opaque.

Of course, that slick surface would present a problem with sewing. Imagine sewing on vinyl or other type of surface that becomes tacky to the sewing foot.

And no, I don’t have a non-stick sewing foot at hand – but I do have paper. Any paper would work but I used thin medical paper that I use for pattern creation. It is lightweight which made it easy to work with and remove.

Since I sewed my bags right-sides-together, it was actually easiest to sew by sandwiching my fabric between two sheets of paper. This made sewing a breeze. Then I simply peeled the perforated pieces away when finished.

I sandwiched my fabric in paper for smooth sewing.

I used cotton shoelace like ties that I bought on my last visit to the Trims On Wheels booth at the Expo. I’ll be seeing them this coming Thursday – for more trims for this year’s Halloween costume!

I have already tested my produce bags. Yes, the clerk, or me has to open the bag to see what’s inside when I’m going through the checkout. They have to twist and turn the plastic bags too, so I’m not really convinced this is a valid sacrifice – if you’re looking for an argument against.

If the bag doesn’t get wet, I can just toss it back on my car seat. If it is wet from produce or wet greens, I can turn it inside-out and rinse or toss it in the laundry.

My test bag went right though a normal wash. I didn’t see a need to dry it and probably won’t – I’m afraid of it melting some of the food-safe side. But it didn’t matter because it dried so fast it truly wasn’t necessary.

My next shopping excursion will include all of my bags. I plan on waving them around so that other people will be so impressed they’ll say – “WOW! How can I get my hands on some of those fabulous bags?”

I would love to hear how you are dealing with your own sea of plastic and whether or not you’ve used any kind of Eco-Friendly fabrics in your sewing.

Thanks for reading, Auntie V

Has anybody ever shopped at Vapin USA Vape Store in 805 6th Ave #C?

I think this is among the most important information for me.

And i’m glad reading your article. But should remark on few

general things, The website style is perfect, the articles

is really nice : D. Good job, cheers

Just desire to say your article is as amazing. The clarity in your post is just spectacular and i can assume you’re an expert on this subject.

Well with your permission allow me to grab your feed to keep up to date with forthcoming post.

Thanks a million and please carry on the rewarding work.